Our Medical Device Development Services - Delivering Remarkable Outcomes Through Every Step of the Process.

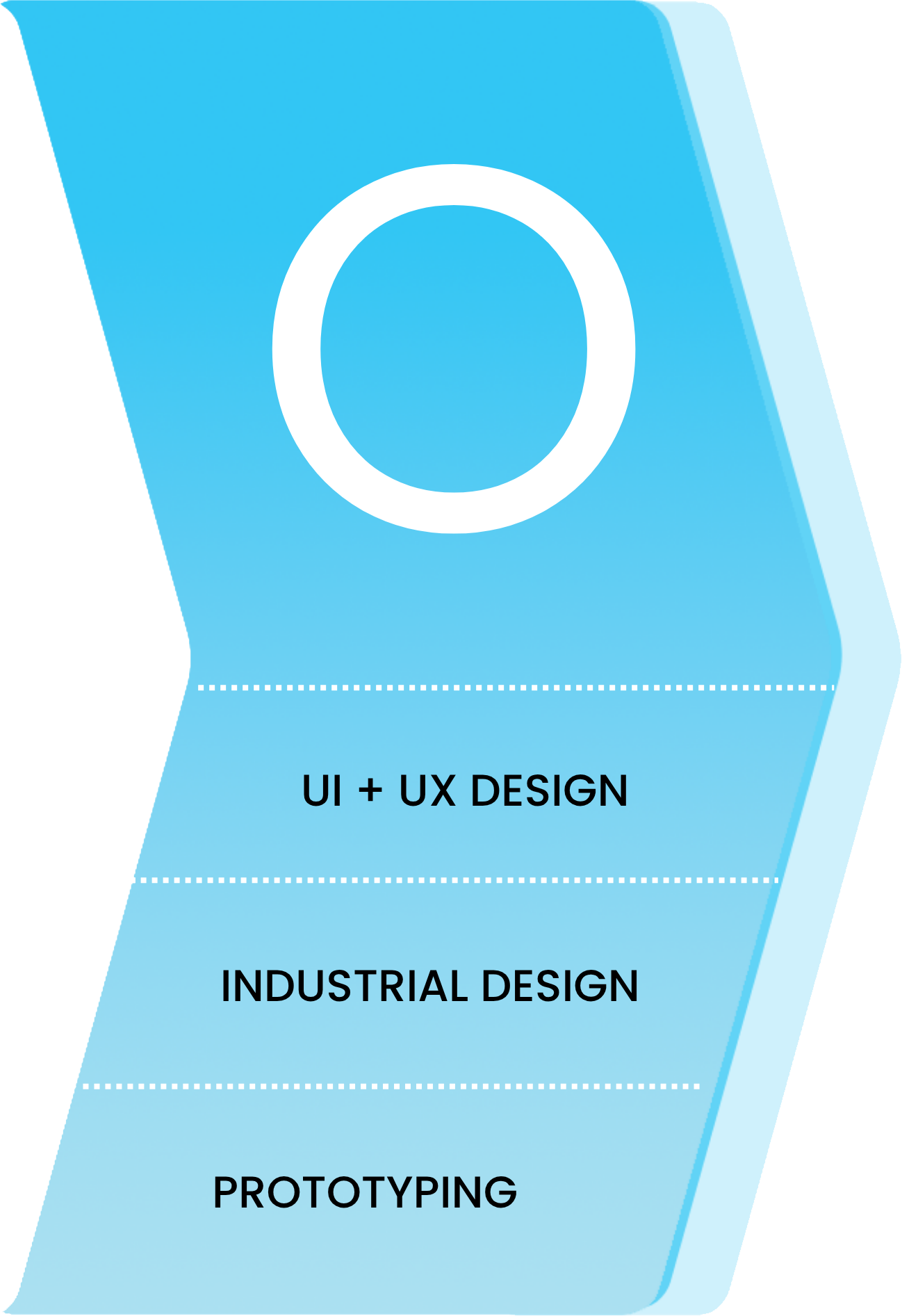

O P T I M I Z E

UI + UX Design - Focuses on optimizing the user experience considering clinical safety and efficacy. [Read More UI] [Read More UX]

Industrial Design - Well crafted, ergonomic, visually compelling design that reflects your brand identity. [Read More]

Prototyping - Enables quick validation of human factors and overall usability. [Read More]

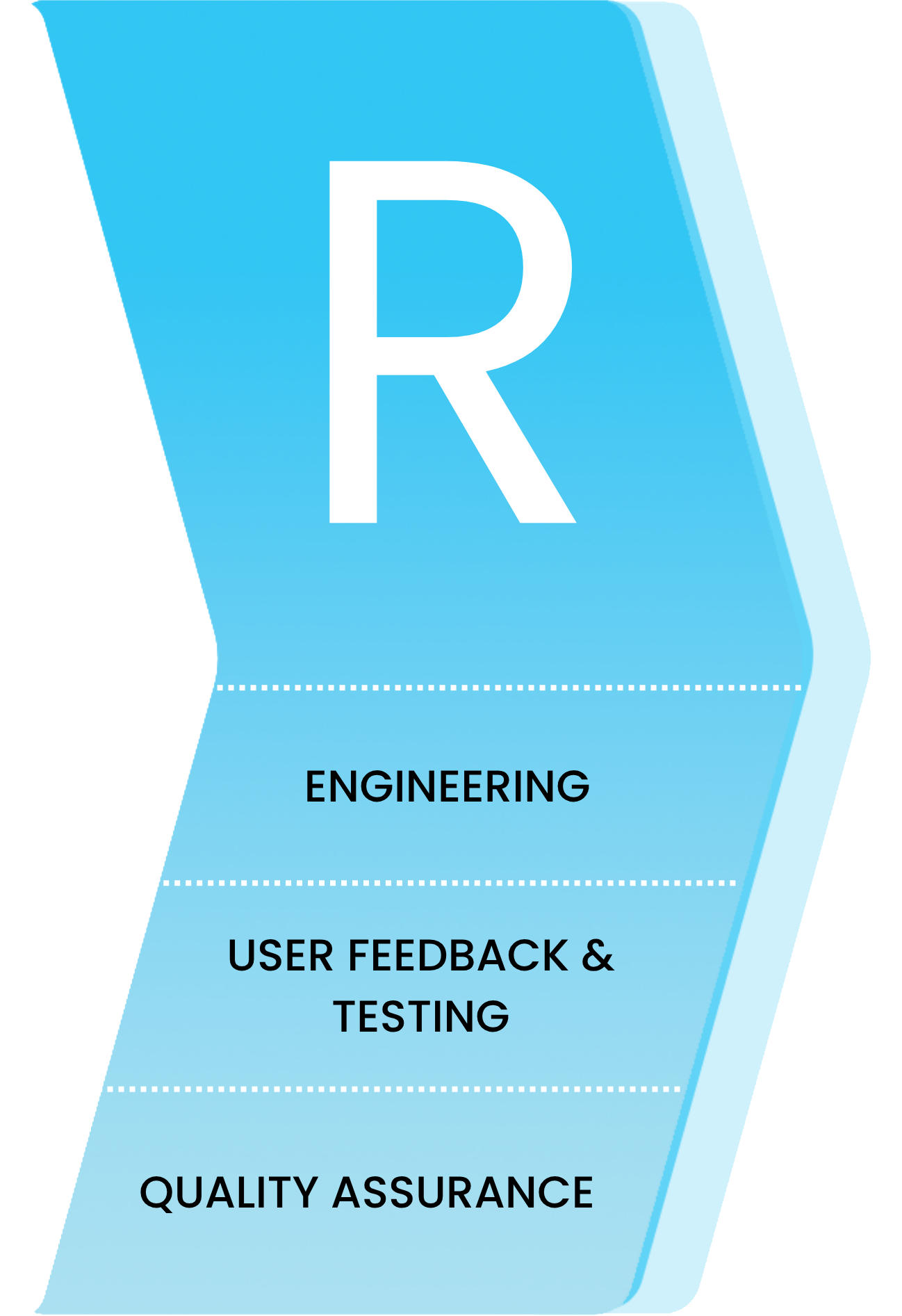

G U I D E

Regulatory Compliance - Guarantees FDA certification. [Read More]

Formative & Summative - FDA-required evaluations integrated throughout development (formative) to guide direction, and post-completion (summative) to confirm goals are met. [Read More]

510K Submissions - Strategic planning from the project start guarantees regulator success. [Read More]

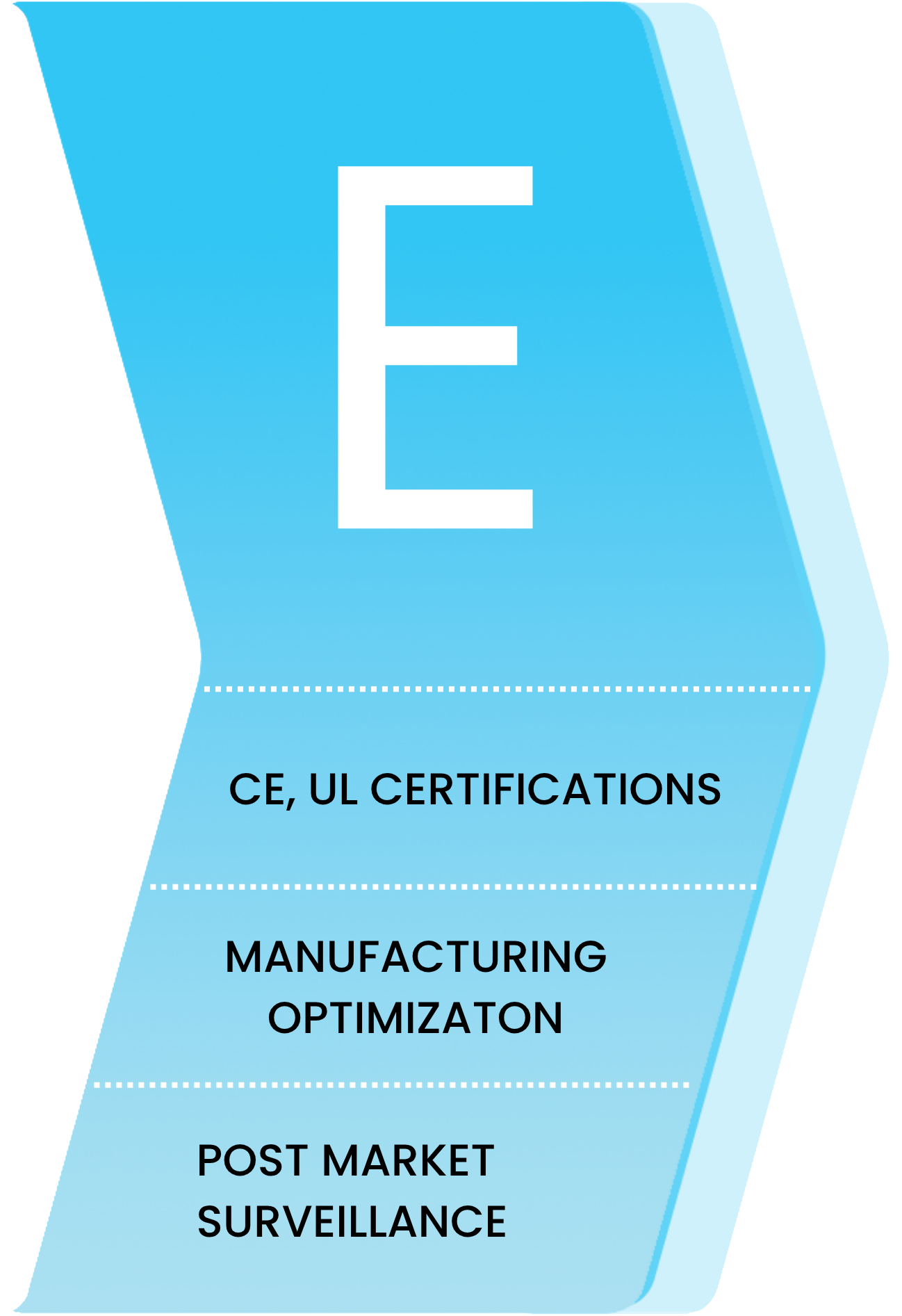

E X E C U T E

CE, UL Certifications - Ensures compliance with international safety and quality standards. [Read More]

Manufacturing Optimization - Streamlining for cost-effective, scalable production. [Read More]

Post Market Surveillance - Monitors device performance, ensures continued compliance, and supports proactive risk management post launch. [Read More]

Frequently Asked Questions

-

We are a full-service, ISO 13485-certified, USA-focused, strategic medical device development partner for hundreds of Class I, II, and III medical devices. Our certification proves our commitment to quality management systems and regulatory compliance.

Our team has over thirty years of extensive experience in medical device development. We can provide start-to-finish product development services that reduce time to market while complying with regulatory requirements and quality standards. Our FORGE design process leads our clients through the process every step of the way, from initial concept to commercialization.

We have worked with hundreds of clients, including Verb, Insulet, Smith & Nephew, RadiaDyne, and Boston Scientific. Our clients came to HaA PD with challenges they faced during medical procedures, patient monitoring, and product re-design. We supplied our expertise and professional know-how, developing medical devices that met their standards and helping them improve them.

We have developed a range of cardiovascular devices, catheters, monitoring systems, implantable devices, minimally invasive tools, robotic components, and precision cutting instruments throughout our work. We have also developed monitoring systems, diagnostic equipment, point-of-care testing devices, and imaging components.

-

HaA Product Development specializes in developing Class I, II, and III medical devices across multiple areas. Our six areas of expertise are surgical instruments, precision equipment, therapeutic devices, diagnostics, wound care, and infusion. Our portfolio includes cardiovascular devices, surgical instruments, diagnostic equipment, and drug delivery systems. We have brought hundreds of medical devices to market and have experience with everything from simple Class I devices to complex Class III implantable devices requiring PMA approval.

-

Development timelines vary significantly depending on device complexity, regulatory pathway, and class designation. Class I devices may take 6-12 months, while Class II devices requiring 510(k) clearance can take 12-24 months. Class III devices requiring PMA submissions can take 3-5 years due to clinical trials and regulatory complexity. Our FORGE platform methodology helps optimize timelines through integrated planning and parallel development Activities.

-

For research and analysis, we conduct the Ncredible framework, which is inclusive of stakeholder interviews and contextual interviews to gain a deeper understanding of real-world device usage. We run in-person observation and focus groups to gain insights into clinical workflows and user needs so that the medical device we manufacture fits the client’s needs and expectations. We do this to identify concerns and false beliefs to ensure we are creating a product that works. The HaA PD team also organizes co-creation research and development sessions, as well as journey mapping exercises, to verify that devices meet actual clinical procedures and patient experiences.

During the research and analysis stage, we conduct surveys and questionnaires to gather quantitative data complemented by competitive benchmarking analysis and thoroughly investigate past case studies. Heuristic evaluations and usability testing assess and confirm our design decisions. Simultaneously, we conduct task analysis and trend analysis to inform future development directions. These inputs help us to develop personas that our team uses to verify our design decisions throughout the product development process.

To further support our designs, we conduct voice-of-customer interviews and key opinion leader (KOL) interviews to gain an effective clinical perspective on device requirements. To meet stakeholder needs, we work with user profiles and user groups. Field research and user interviews help our teams narrow down the clinical environments and user behaviors that best match the medical device.

-

Our device design approach for concept development combines rigorous market research with visual design excellence in a manner that makes sure every interface concept meets the required clinical requirements. Our multidisciplinary team creates highly developed visual hierarchies and interfaces that guide users through complex processes without sacrificing visual appeal. We create responsive, scalable interfaces that adapt to changing configurations of medical equipment, remaining consistent across different clinical settings.

Through rigorous concept feasibility testing and iterative prototyping, we define interface designs against real-life medical scenarios. Our prototyping range ranges from wireframes to interactive graphical models actively tested within healthcare environments, being wholly compliant with all regulatory needs but with interface solutions that reduce visual fatigue, legibility, and user error throughout life-critical medical procedures.

-

Our UX design and concept creation services cross the gap between innovative new technology and life-saving healthcare solutions through commitment-based market research and clinical workflow analysis. Our process of concept development begins with extensive user research, and we make sure that every device concept addresses substantiated clinical requirements while maintaining competitive differentiation in the continuously changing medical device industry.

Through systematic concept feasibility testing and iterative prototyping, we test designs against real-world medical environments. Our prototyping facilities range from wireframes through interactive models tested directly in healthcare environments, achieving compliance with regulations while contributing directly to improved patient outcomes and optimizing healthcare delivery through excellence in user experience.

-

Human factors engineering includes developing a procedural map to optimize device usability to understand human factors and feature requirements. We implement use-related risk analysis to find potential use errors and associated hazards. Heuristic analysis assesses our interfaces against established usability principles specific to medical devices.

Formative evaluations provide iterative feedback during development, while summative assessments measure the effectiveness of the final design. Iterative design testing emphasizes continuous improvement throughout the development process. The use and user interface specification documentation are based on design feedback and findings from quantitative and qualitative exercises.

Human factors and usability engineering planning integrate human factors engineering (HFE) throughout the development process. If we spot potential use errors, we adjust our design accordingly. Our team develops user and usage requirements to support design decisions throughout development.

-

Industrial design services include conceptual sketches and detailed renderings throughout the medical device design process. Color, material, and finish (CMF) are based on clinical environment requirements, cleanability, and durability. Our medical devices are carefully designed to match our clients' corporate identities while maintaining full clinical functionality.

Our iterative design processes incorporate feedback loops with clinical stakeholders and regulatory requirements. We organize concept feasibility analyses early in development to assess technical and commercial viability. Breadboard refinement and working models provide rapid prototyping and design validation.

At HaA PD, we always seek ways to reduce costs and produce competitively priced medical devices. We have initiated cost reduction initiatives that are integrated throughout the design development process. We validate design concepts through initial prototype testing and constantly look for improvement opportunities before investing in production tooling.

-

Engineering services include developing device requirements so that all specifications are clearly defined and traceable. Documentation begins early in our process with detailed drawings that follow ASTM EY 14.5 tolerancing. This defines manufacturing issues early, including injection-molded parts and metal parts, all of which are integrated into a master assembly with part-to-part relationships.

Just prior to design freeze, we require a complete part tolerance overview. This is usually done by the design engineer who has familiarity with the overall assembly, thus ensuring proper tolerancing. After this, a full DFM is performed, which includes part-to-part clearances.

The term that we use internally in our office is a tolerance-friendly design, meaning that each part can fit within the parameters and performance of the machine or equipment that is making it. Depending on the process, molded or machined stamps are produced.

This design experience results in lower costs and more efficient production lines. It also makes all parties involved feel accomplished. When the ultimate output is tolerance-friendly, cost is reduced, which expedites the manufacturing setup. This makes management happy because the time to market and sales is drastically reduced.

-

Our range of medical services includes design for manufacturing (DFM) and design for assembly (DFA) optimization, which helps reduce production costs and improve quality. We source from the US and international supplier networks to achieve the best balance between cost, quality assurance, regulatory compliance. We always look for ways to reduce costs through better engineering and manufacturing techniques, all while maintaining quality, regulatory compliance, and optimal performance.

We provide complete documentation packages for our manufacturing process, including detailed work instructions, quality plans, and inspection protocols. Also, we assist our clients with regulatory submission and process validation support. Our HaA PD patent assistance services protect intellectual property throughout development and manufacturing.

Our team helps with technology transfer for a smooth transition from development to production. Thanks to our expertise and professional experience, we minimize startup issues and ensure your medical device reaches the market quickly and efficiently.

-

HaA PD provides comprehensive support for both design and manufacturing. We develop and test products with manufacturing requirements in mind, guiding them from initial concept through prototyping and validation. Whether we hand your device off to your manufacturing team or work with our trusted device contract manufacturing partners, we ensure a smooth production process.

-

HaA can ensure that your medical device is compliant with FDA QSR (21 CFR 820) and can develop and implement an ISO 13485:2016 compliant quality system for your company. Our team conducts gap assessments, develops regulatory submission content, and provides ongoing regulatory guidance throughout the product lifecycle. Our philosophy is quality is in everything we do, some of the standards that we are well versed in are as follows iso 14971 risk management, ANSI HE75 human factors, I.e. C 62366 usability, ISO 10993 biocompatibility, ISO 11135 sterilization, IC 6/06/01 electrical equipment.

-

HaA PD provides patent assistance services, including IP landscape analysis, freedom-to-operate assessments, and patent filing support. We also handle external research and documentation, and protect your innovations. We implement comprehensive confidentiality agreements and IP protection protocols throughout the development process. Our team conducts patent searches, evaluates existing intellectual property (IP), and develops strategies to protect our clients' innovations.

-

We have a global medical device network and can help our clients scale their sales globally and cost-effectively. HaA PD has offices in the United States and Asia, and we work with excellent worldwide manufacturers who can produce your medical device according to specifications.